RecurDyn - 5 Advantages 글 편집 글 편집 (이전 에디터)

1. Pre/Post environment specialized for MBD analysis

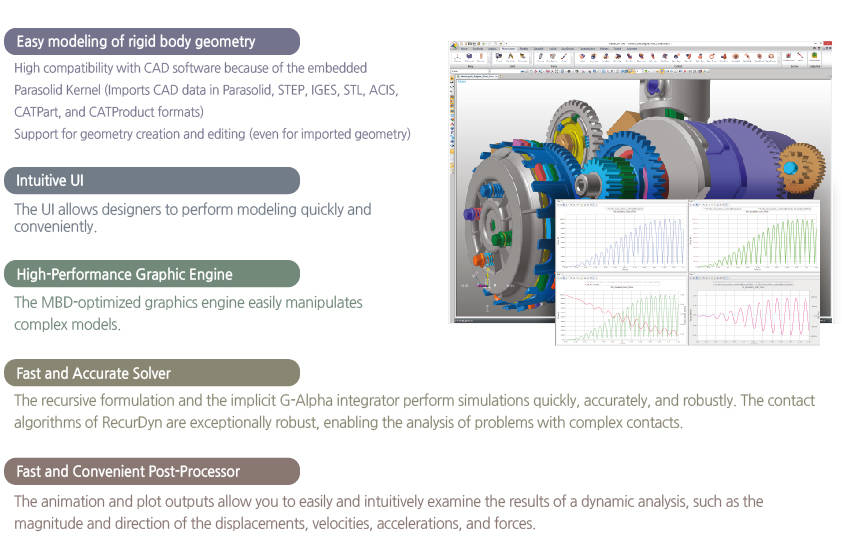

MBD analysis requires a complete modeling environment to enable the definition of a variety of mechanical systems, including the definition of inputs and post processing (animation and plotting). RecurDyn provides a fast and efficient modeling environment. The MBD optimized UI is based on the feedback from experts and engineers in the field of MBD.

2. Fast, accurate and diverse Contact library

Sophisticated technology is required to calculate contacts in a mechanical system. RecurDyn enables you to quickly and accurately analyze contacts in a complicated model using world-class contact algorithms. In addition, the Contact library is optimized for specific geometries such as ellipsoid, cylinder, or box.

3. Analysis of the motion of an assembly containing rigid and flexible bodies

MFBD technology can accurately simulate a system containing rigid and flexible bodies. It is possible to simulate nonlinear elastic cases including contact and large deformation as well as linear elastic cases. The processes of mesh creation and durability analysis are also supported within RecurDyn.

4. Various application toolkits

Various toolkits support complex sub-systems, including: media transport products such as printers and copiers, track assemblies on products such as construction machinery, military vehicles and recreational vehicles and machinery components such as gears, belts, and chains. The toolkits allow the user to perform modeling for a specific industry field quickly and easily and then conduct an accurate analysis of complicated mechanical systems with specialized solvers.

5. Scalability for multidisciplinary integrated analysis