DriveTrain - Gear and Bearing Simulation Software 글 편집 글 편집 (이전 에디터)

Gear Simulation is essential for analyzing gear performance, optimizing design, and ensuring reliability in various industries like automotive, robotics, and machinery.

Gear train simulation using RecurDyn/DriveTrain

RecurDyn/DriveTrain is a gear simulation software that enables users to model and simulate the components of a drivetrain consisting of gears, bearings, shaft, and other components (especially for gear simulation and bearing simulation). It consists of 3 toolkits: GearKS, BearingKS, and Shaft. Users can easily simulate and analyze drivetrain systems with specialized modelers that can easily create gears, bearings, and shafts, a specialized solver, and dedicated post-processing.

In particular, GearKS and BearingKS have been developed through the technical partnership with Gleason’s KISSsoft . This allows users to accurately capture not only transmission error for noise and vibration evaluation but also other results by using the RecurDyn's dynamic solver and KISSsoft's Gear Analytic Contact.

*KISSsoft provides specialized libraries for gear simulation and bearing simulation.

*RecurDyn/DriveTrain is a gear simulation software equipped with world-class dynamic solver and gear analytic contact.

RecurDyn/GearKS provides an intuitive Gear Modeler and built-in KISSsoft UI for gear simulation. It supports Spur, Helical, and Planetary Gear, enabling analyses with detailed gear geometries. This gear simulation toolkit predicts accurate Transmission Errors through theory-based contact specialized for gears.

RecurDyn/GearKS provides an intuitive Gear Modeler and built-in KISSsoft UI for gear simulation. It supports Spur, Helical, and Planetary Gear, enabling analyses with detailed gear geometries. This gear simulation toolkit predicts accurate Transmission Errors through theory-based contact specialized for gears.

1. Gear Analytic Contact specialized for gear analysis (SMP is supported)

2. Provides various gear simulation results including Transmission Error (TE)

3. Intuitive gear modeler

4. Supports Spur Gears, Helical Gears, and Planetary Gears

5. Supports 3D gear geometry and detailed tooth modeling

6. Provides various Tooth Tolerance libraries and Material libraries

7. Automatic calculation of gear backlash based on inputs

8. Detailed modeling and simulation/post-processing through built-in KISSsoft UI specialized for 3D gears

- Precise 3D gear design with parameters used for actual gear design

- Interoperability of the gear models between KISSsoft and RecurDyn (Z12 Import, Export)

- Supports gear static analysis

- Various simlation results such as stress distribution on the gear tooth surface

Intuitive and easy-to-use UIs for efficient gear train simulator

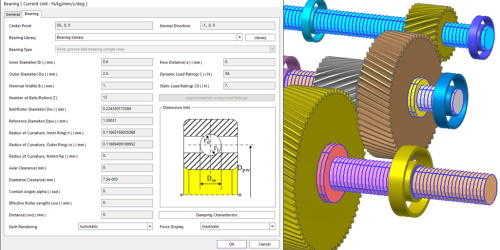

RecurDyn/BearingKS provides Intuitive Bearing Modeler to generate and simulate 15 different types of bearings. This bearing simulation toolkit also provides bearing database of 8 global brands and bearing creations with user-defined parameters are now available.

1. Intuitive bearing modeler

2. Bearing creation using user input parameters Bearing database of 8 global brands

3. 15 different types of bearings (ISO/TS 16281)

4. Provides bearing database of 8 global brands

- SKF, IBC, TIMKEN, KOYO, KRW, NSK, FAG, INA

- Bearing creation with tens of thousands of libraries

5. Estimates internal geometry parameters of bearing based on diameter and load rating of ball and roller

6. Provides position, velocity, acceleration, and reaction force of bearing at each time of simulation

* BearingKS is often used with GearKS together for gear train simulation.

Bearing libraries for accurate gear and bearing simulation

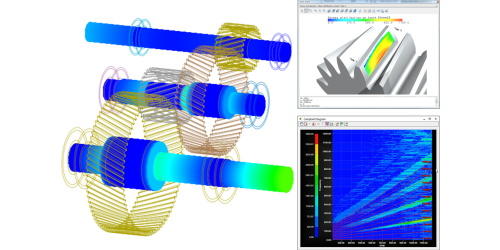

RecurDyn/Shaft provides Intuitive Shaft Modeler to calculate the deformation and torsion of shaft using flexible beam elements. It allows to automatically create FDR for bearing and gear engagement and supports Planetary Shaft for planetary gear, providing post-processing function through Scope specialized for Shaft.

RecurDyn/Shaft provides Intuitive Shaft Modeler to calculate the deformation and torsion of shaft using flexible beam elements. It allows to automatically create FDR for bearing and gear engagement and supports Planetary Shaft for planetary gear, providing post-processing function through Scope specialized for Shaft.

1. Intuitive shaft modeler for easy and convenient modeling

2. Flexible shaft using beam element to calculate the deformation and torsion

3. 3D visualization of the beam shape based on the beam property

4. Automatic creation of RBE (FDR) at the point where bearings and gears are engaged

5. Supportd Planetary Shaft modeling for planetary gear.

6. Supports ‘shaft scope’ to intuitively check the shaft deformation and other results.

* Shaft is often used with GearKS and BearingKS together for gear simulation.

User-friendly shaft modeler for gear simulation

User-friendly shaft modeler for gear simulation

6 Advantages of RecurDyn/DriveTrain (for gear train simulation)

Accurate Gear Analytic Contact

Consideration of detailed gear parameters

Accurate prediction of Transmission Error

Easy Modeling with Specialized UI

Modelers for gears, bearings and shafts

Built-in KISSsoft UI for gears

Various Bearing Libraries

17 different types of bearings

Provides bearing database of 8 global brands

( SKF, KOYO, TIMKEN, FAG, IBC, INA, KRW )

System Modeling

Assembly analysis

using MFBD technology

Transient Analysis using Dynamic Solver

Dynamic Transmission Error evaluation

Gear Misalignment by various causes can be considered

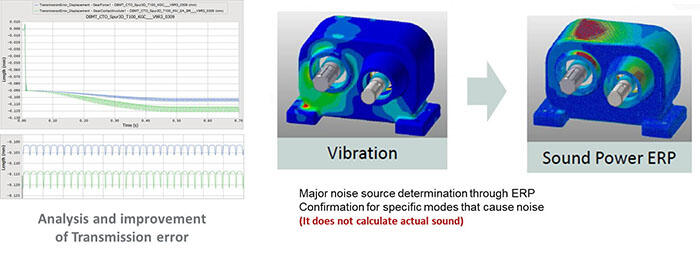

Check the Transmission Errors

Transmission Error determination

Campbell Diagram (Order Tracking Analysis)

Various results of gears, bearings, and shafts can be reviewed

Advantages of Gear Analytic Contact for Accurate Gear Simulation

Since Transmission Error is a very small value (µm), accurate contact calculation is crucial for accurate gear simulation. FunctionBay provides accurate Gear Analytic Contact through technical cooperation with Gleason/KISSsoft for advanced gear simulation.

- Theory-based contact calculation considers detailed gear design parameters.

- Considers deformation of gear teeth

- Considers tolerance of gear teeth

- Contact available in dynamic gear simulation

Optimized algorithm for gear simulation

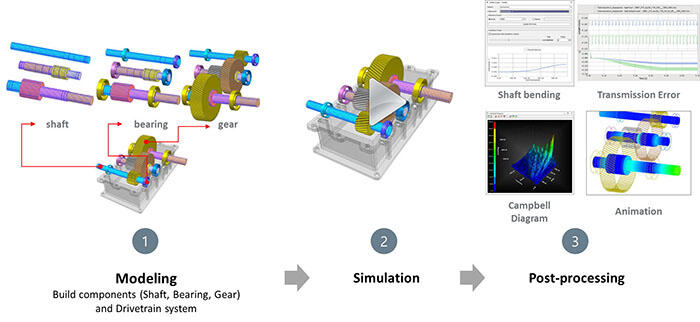

Gear train simulation process using RecurDyn/DriveTrain

3 steps of the process (modeling/simulation/post-processing) to use RecurDyn/DriveTrain, a gear simulation software.

Benefits of RecurDyn/DriveTrain for Gear Simulation

1. Save time and cost by performing simulations under varying conditions in virtual environment

- Precise and detailed gear design

- Various types of bearings

- Various bearing positionings

- Varying operating conditions (rotation speed, torque)

2. Evaluation of products that are difficult to be tested

- Performance evaluation in extreme conditions, such as space and deep sea

- Micro gears used for small parts that are difficult to be measured (micro gear simulation)

3. Various simulations and performance evaluations of the drivetrain system

- Performance evaluation of the system consisting of gears, bearings, and shafts

- Effect analysis caused by gear vibration and shaft deformation

- Whine noise analysis through Transmission Error

- Rattle noise analysis caused by backlash

- Design verification for major noise source determination and noise reduction ( RecurDyn/Acoustics is required)

RecurDyn/DriveTrain provides useful features for fast and accurate gear simulation.

Watch a free webinar now to learn how to conduct gear simulation with RecurDyn/DriveTrain!