{{ post.title }}

글 편집

글 편집 (이전 에디터)

{{ post.author.name }}

Posted on

| Version | {{ post.target_version }} | Product |

{{ product.name }}

|

|---|---|---|---|

| Tutorial/Manual | {{ post.manual_title }} | Attached File | {{ post.file.upload_filename }} |

Question : I want to use a flexible body. Should I use FFlex or RFlex to model it?

Answer : You must consider many conditions when selecting whether to apply RFlex or FFlex properties. In most cases, nonlinearity and simulation speed are the most important factors to consider

Refer to the following guidelines.

1. FFlex models are better in the the following cases:

- Parts that are so flexible that they deform easily (such as paper, belts, and wires).

- Loads that are imposed on different locations (when contact occurs but the contact points change over time).

- It is necessary to calculate stress accurately (in particular, when there are stress concentrations).

- Models that require non-linear characteristics, such as buckling, plasticity, or super elasticity.

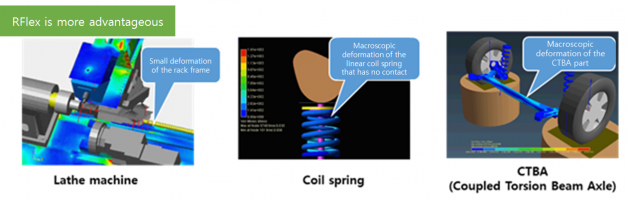

2. RFlex models are better in the following cases:

- Large FEM models in which the load points do not vary significantly (for example, an automobile frame).

- When the deformation of a flexible body is important and this functions as a mechanical property such as in coils and plate springs.

- When no contact occurs and the load points are consistent (for example, links).

- It is necessary to interact with the control system and, therefore, rapid simulations are needed.

The above cases only provide a few guidelines. To select the correct flexibility for a model, you must consider the characteristics of the model, the purpose of the simulation, and many other aspects.