FFlex Thermal 글 편집 글 편집 (이전 에디터)

Overview

- RecurDyn FFlex is possible to consider the thermal stress and thermal expansion due to a temperature change within a flexible body.

- Boundary conditions can also be set to include additional heat transfer effects such as Convection, Heat Generation, or Heat Flux.

-

Supported elements

- Beam2

- Shell3, Shell4, Shell9

- Solid4, Solid5, Solid6, Solid8, Solid10, Solid26

Features

1. Material Properties

-

Thermal Characteristics: The temperature properties for material can be specified in the material Properties window. (Elastic/Isotropic only)

- Thermal Coefficient (Coefficient of thermal expansion)

- Reference Temperature (Temperature at which no thermal stress occurs in the material or initial temperature in RecurDyn)

- Specific Heat

- Thermal Conductivity

2. Thermal Conductivity Analysis

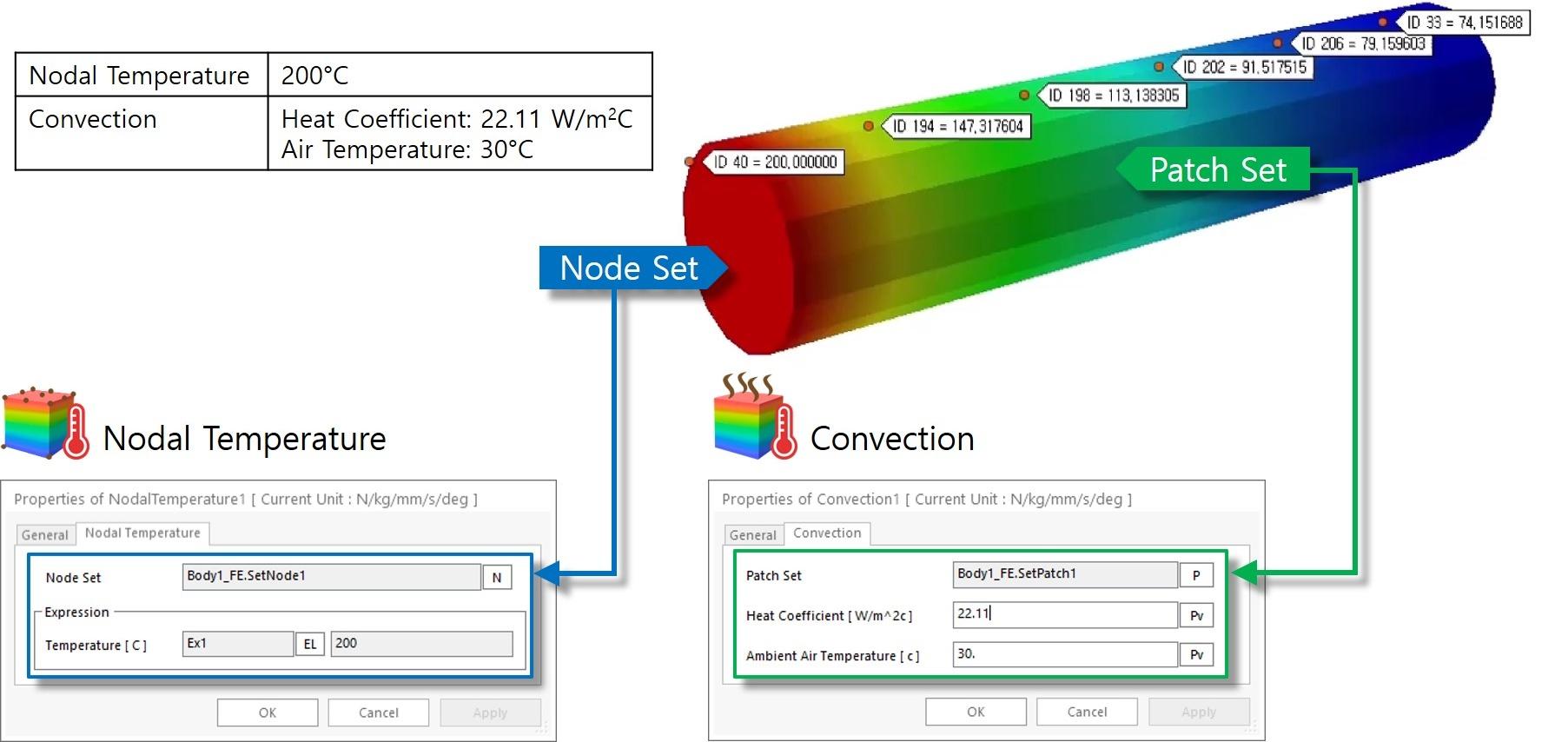

- Nodal Temperature: Defines the temperature condition by entering an Expression for a Node Set.

- Heat Flux: Defines the amount of heat influx per unit area by entering an Expression for a Patch Set. The area inflow direction can be set to either Up or Down.

- Convection: It is now possible to select a Patch Set and enter a Heat Coefficient and Ambient Air Temperature to define the amount of surface heat transfer by convection.

- Heat Generation: Defines the energy generated per unit volume by entering an Expression for an Element Set.

3. Thermal Load

- RTL Generation: It is now possible to generate RTL files in CSV file format from the thermal conductivity analysis results of flexible bodies.

-

Thermal Load

- To calculate the thermal load, the temperature of each node is defined using Expression.

- Analysis considering the converted thermal load is possible.

- Applying the RTL file to the thermal load allows an analysis to consider the thermal load without performing a heat transfer analysis.

Benefits

- RecurDyn can perform thermal conductivity analysis without using any other software.

- This allows you to check the effects of thermal expansion and thermal stress of a flexible body when performing multi flexible body dynamics analysis.

- It is now possible to perform dynamic analysis in consideration of thermal stress on the structure and parts of a system that generates a lot of thermal energy and to improve the design for system operation with reliability and stability.

Examples

Example 1. Cooling of Steel Rod

- Analysis Conditions: Cooling by convection from initial temperature 200°C to 30°C

Example 2.Hollow Cylinder with Fixed Temperature & Convection

-

Analysis Conditions: Temperature rise due to convection inside cylinder and fixed external temperature condition

Application

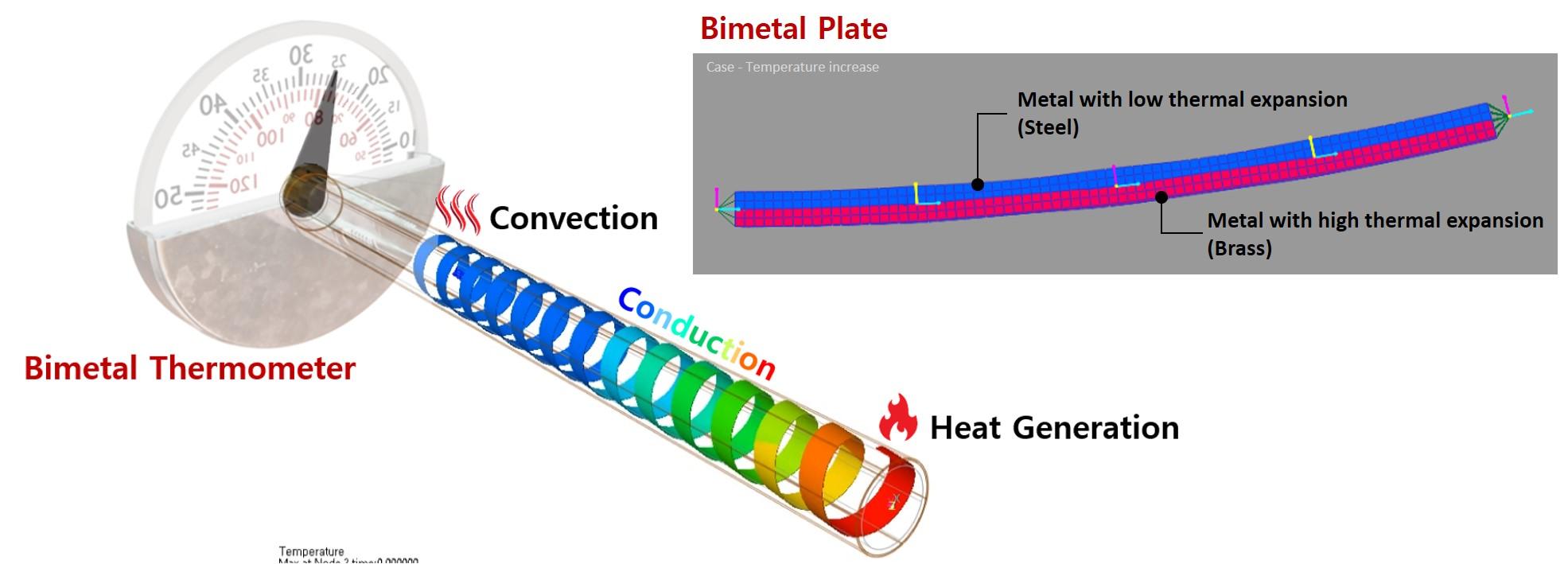

Bimetal Thermometer (Helical Type)

-

Bimetal Thermometer (Helical Type)

- The helix is fixed on one end and the other end will twist or rotate directly proportional to the temperature change

- A calibrated gauge with indicator is attached to the rotating end for direct indication of the sensed temperature

-

RecurDyn Modeling

- Plate Top: Thermal insulation (Steel)

- Plate Bottom: Thermal insulation (Brass)

- Left end: Convection

- Right end: Heat Generation