{{ post.title }}

글 편집

글 편집 (이전 에디터)

{{ post.author.name }}

Posted on

| Version | {{ post.target_version }} | Product |

{{ product.name }}

|

|---|---|---|---|

| Tutorial/Manual | {{ post.tutorial.upload_filename }} | Attached File | {{ post.file.upload_filename }} |

Bicycle Simulation - Automated creation and simulation of the bicycle transmission model

Product: Bicycle transmission system

Analysis Goal: Automation of the repetitive process of bicycle transmission modeling to evaluate the various designs efficiently

Bicycle transmission performance can be evaluated from two perspectives.

One emotional, such as how smoothly and precisely a shift occurs. The other relates to energy, such as how little human power is required to shift and how small the energy loss is during the process of gear shifting.

A bicycle chain has many links. Accurately simulating a bicycle transmission requires precise calculation of contact between the sprockets and all of the chain links. Each transmission simulation model requires many elements to be created, which would be time-consuming if performed by hand.

In particular, a sophisticated contact definition for each chain link is needed that can reduce simulation time, which is also time-consuming. Furthermore, every change in any component design requires the creation of a new bicycle simulation model.

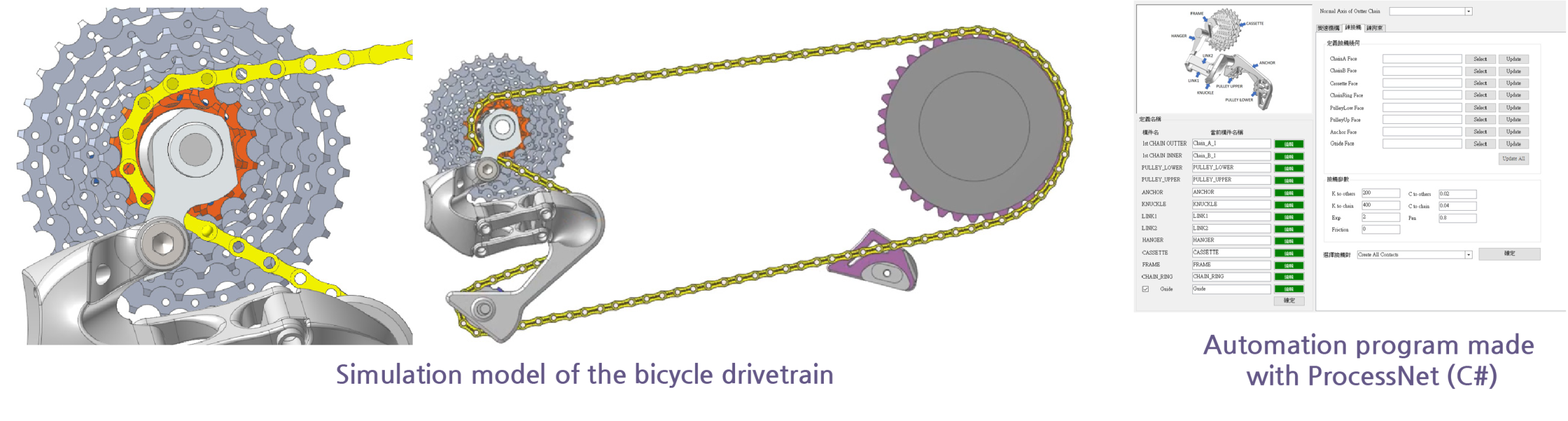

RecurDyn was chosen to simulate these bicycle transmissions because it allows for scripting using the C# language to automate many aspects of model creation. This allowed for a large number of models to be created rapidly, and furthermore, through optimized contact modeling, reduced the bicycle simulation time of each model as well. With this customization, various shapes of the chain link, the installation angle of the sprocket, and the tolerance between the chain roller and the pin were able to be efficiently modeled, simulated, and analyzed.

◆ Process for bicycle simulation

① Imported CAD data of all parts of bicycle transmission, including chain links.

② Used a ProcessNet script written in C# to automate the creation of the bushing forces, the definition of the contact surfaces on the chain links, and the creation of the contact between the sprockets and chain links.

③ Evaluated the performance for various angles of the cassette sprocket.

④ Evaluated the performance for various chain link shapes.

◆ Key Technologies for Analysis: bicycle transmission

- MBD solver and contact algorithm that can accurately simulate a large number of bodies and contacts between those bodies of the bicycle transmission (109 chain links and other bodies, 648 contacts)

- Built-in customization scripting to automate repetitive operations such as creation and modification of many objects

- Bushing force model that can properly model the characteristics of a chain

-

Parallel processing technology for high-speed bicycle simulation

◆ Toolkits for Bicycle Simulation

- RecurDyn/Professional

- RecurDyn/ProcessNet

◆ Customer Challenges

- Difficulty in making prototypes whenever the geometric shape of the components is changed

-

Need for data that is difficult to measure with physical tests

- Need to create another model for every modification of the chain link shape

- Possibility of the long simulation time because of the large number of bodies and contacts in the bicycle model

◆ Solutions for bicycle simulation

- ProcesseNet scripting customization using C# to automate tasks that need to be repeated whenever the chain link and sprocket shapes are changed

- Reduction of simulation time by using the specific surface of the chain link for contact, not the entire surface

- An MFBD solver that efficiently utilizes parallel processing for faster simulation (used 8 cores.)

◆ Outcomes

- The bicycle transmission model was created rapidly using the built-in customization tools for automation.

- The relationship between the derailleur position, the install angle of the sprocket, the shape of the chain link, and the time to complete the shift were successfully identified.

- Verified the possibility and ease with which the chain can come off.

- The contact force between the chain link and the other parts was obtained.

- The force and torque required to execute a gear shift were identified.

◆ Other Applications