{{ post.title }}

글 편집

글 편집 (이전 에디터)

{{ post.author.name }}

Posted on

| Version | {{ post.target_version }} | Product |

{{ product.name }}

|

|---|---|---|---|

| Tutorial/Manual | {{ post.manual_title }} | Attached File | {{ post.file.upload_filename }} |

Mesh failures can occur for various reasons. (Usually when the geometry is too complicated)

Please refer to the following guidelines to resolve the mesh failures.

1. Shell mesh shows the better success rate of meshing than Solid Mesh.

If possible, using shell element type is recommended

2. Tetra type element shows the better success rate of meshing than Hexa type element

3. When mesh failure occurs, using same value for Max. Element Size and Min Element Size often resolve the failure.

(but not always)

(the first candidate for the value is the average of Min/Max. If it fails again, use the average of Min and the 1st average. (as if bisection method))

Min: 2, Max: 6 >> 4 ( (2+6)/2 )

after then, 2 ( (2+4)/2 )

4. The more fundamental solution is simplifying or refining the geometry before meshing.

- Body Edit Mode : Simplifying using [Geometry]-[Simplify]- Delete Face, Delete Edge

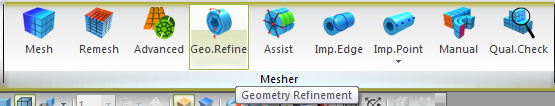

- Mesher Mode: Refining using [Mesher]-[Mesher]-[Geo.Refine]